Understanding Forged Fittings: What You Need to Know

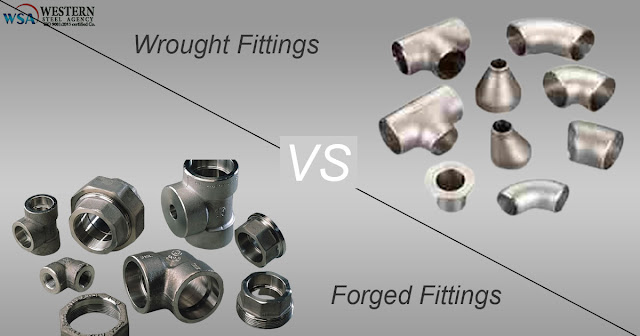

When it comes to connecting pipes in industrial settings, one crucial component often used is forged fittings. These fittings play a significant role in ensuring a secure and reliable connection between pipes, which is vital for the smooth operation of various systems. What Are Forged Fittings? Forged fittings are specialized components used to connect pipes in different systems. They are called "forged" because they are shaped by applying pressure to heated metal, a process known as forging. This method makes them incredibly strong and durable, ideal for handling high-pressure and high-temperature environments commonly found in industries like oil and gas, chemical processing, and power generation. Types of Forged Fittings There are several types of forged fittings, each designed for specific purposes: 1. Socket Weld Fittings: These fittings have a socket at one end and are welded onto the pipe. They are used for small pipe diameters and low-pressure applications. 2. Thr