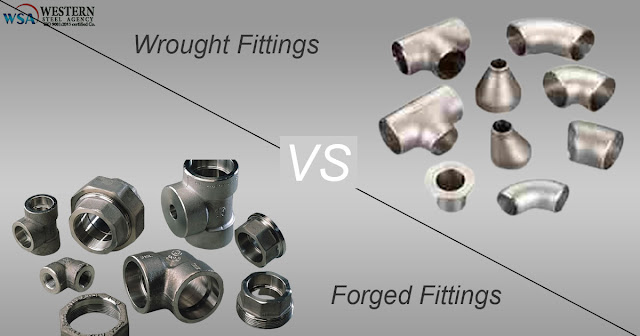

Wrought Fittings vs Forged Fittings: What is the Difference

Are you planning a plumbing project or need fittings for pipelines? It's important to know the difference between wrought fittings and forged fittings to make the right choice. Let's break it down in easy language. Wrought Fittings: Imagine wrought iron – strong, durable, and versatile. Wrought fittings are somewhat like that. They're made by shaping metal, usually steel or iron, by hammering, bending, or rolling it into shape. This process makes them strong and resistant to corrosion. Pro Durability: Since they're shaped under high pressure, wrought fittings are tough cookies. They can handle high-pressure applications without breaking a sweat. Corrosion Resistance: Nobody likes rust, right? Wrought fittings have good resistance to corrosion, making them ideal for outdoor or harsh environments. Customization: Want fittings in a specific shape or size? Wrought fittings can be customized to fit your needs. Just ask! Cons Cost: Making wrought fittings involves more labo...